Humming quietly in the background, going entirely unnoticed, dust collection systems keep our workshops clean and efficient. They’re the unsung heroes in our midst. Not only do they keep our spaces tidy, but they play a vital role in safeguarding the health of our teams and the longevity of our equipment.

But here’s the thing – the story doesn’t end when you install one of these systems. To truly reap the rewards, it’s essential to maintain them diligently. In this blog, we’re going to guide you through the art of dust collection system maintenance. Think of it as looking after a valuable investment because that’s precisely what it is.

We’ll delve into the routines that will keep your system running smoothly. We’ll show you how to troubleshoot common issues and why regular inspections are your best friend.

Are you ready?

Let’s roll up our sleeves, don our maintenance hats, and ensure that your dust collection system continues to be your unwavering partner in clean, safe, and efficient woodworking.

Protecting Your Investment

I’m going to guess that you did not make the decision to invest in a dust collection system lightly. It’s a financial commitment, and like any investment, it requires care and attention to ensure it flourishes.

With that in mind, let’s explore how you can ensure your investment pays off over the years.

Understanding the Financial Investment

Let’s start with the basics. When you committed to investing in your dust collection system, you wanted to create a safer, cleaner, and more efficient workspace. Sure, the initial cost may have seemed significant. But this was an investment in the longevity of your woodshop and the well-being of your team.

The Role of Proper Maintenance

Now, here’s where the story gets interesting. Taking care of your dust collection system is like tending to a valuable garden: The more you nurture it, the more it gives back. By regularly maintaining your system, you ensure that your initial investment keeps paying dividends in the long run.

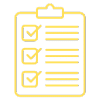

Imagine you’ve got a beautiful sports car. Without regular oil changes, tire rotations, and check-ups, it won’t perform as it should. Over time, it’ll deteriorate. Your dust collection system is no different. Regular check-ups, cleaning, and filter replacements are the oil changes and tire rotations for your system.

These regular practices keep it running smoothly.

The Impact on Operational Efficiency

Now, let’s talk about how a well-maintained dust collection system positively influences your workshop’s operational efficiency. When your system is in top shape, it works tirelessly to remove dust and particles from the air. Such a system helps to create a pristine environment for your employees. Clean air means healthier workers, fewer sick days, and a happier, more productive team.

Efficiency doesn’t stop there. Your dust collection system also plays a crucial role in the longevity of your machinery. Dust, as we’ve discussed before, is an abrasive enemy. When it accumulates on moving parts, motors, and electrical components, it can lead to premature wear and tear. This causes more frequent breakdowns and costly repairs.

By investing time and effort into maintenance, you’re not just prolonging the life of your system; you’re also ensuring the longevity of your valuable equipment. Fewer breakdowns mean less downtime and reduced maintenance costs. A well-maintained system translates to a more efficient and cost-effective woodshop operation.

In essence, a well-maintained dust collection system is a financial investment that keeps on giving. Its impact on operational efficiency is nothing short of remarkable.

Now, let’s dive deeper into the routines and practices that will keep your dust collection system in peak condition.

Routine Maintenance Habits

Now that we’ve established why maintaining your dust collection system is crucial let’s roll up our sleeves and unpack the nitty-gritty of routine maintenance. These are the practices that will keep your system humming like a finely tuned orchestra.

The Importance of Regular System Check-Ups

Think of your dust collection system as a skilled conductor orchestrating the performance in your shop. To make sure it is in perfect harmony, regular check-ups are a must. These check-ups are your way of confirming that everything is functioning as it should be. They help you detect issues early on. Catching issues in the early stages helps you prevent small problems from snowballing into larger, costlier complications.

Regular check-ups are more than just a quick glance. They involve a comprehensive inspection of your system’s components. From the ductwork to the hoods, fans, and filters, each element must be in top form for your system to work efficiently.

The Benefits of Establishing a Maintenance Schedule

Without a schedule, you can easily overlook or postpone maintenance. Establishing a maintenance schedule is like setting regular doctor’s appointments for your system. It ensures that your system gets the attention it deserves at the right intervals.

Having a schedule in place makes maintenance a predictable and repeatable part of your shop’s operations. This not only prevents neglect but also allows you to plan for maintenance activities efficiently. Scheduled maintenance is less disruptive than dealing with emergency breakdowns. Accordingly, it facilitates a more streamlined and cost-effective shop.

Filter Replacement: Frequency and Process

Filters are the heart and lungs of your dust collection system. They capture and clean the air, resulting in a safe and dust-free woodshop. Filters, however, have a finite lifespan. Their replacement is a critical part of maintenance.

The frequency of filter replacement depends on various factors. The type of filter, the volume of dust produced, and the air quality requirements all play into determining how often you will need to replace your filter. Be sure to consult your system’s manual for specific guidelines. As a general rule, though, filters should be replaced before they become too clogged. If you are regularly inspecting your system, you will notice when the filters get covered in dust particles.

Here are seven simple steps for replacing your filter:

- Shutdown: Ensure the system is turned off and unplugged for safety.

- Access Filters: Locate the filters and open the access panels or doors.

- Remove Old Filters: Carefully remove the old filters, following manufacturer instructions.

- Clean Surrounding Area: Take the opportunity to clean any dust or debris in the filter housing.

- Install New Filters: Gently insert the new filters according to the manufacturer’s guidelines.

- Secure Access Panels: Close and secure the access panels or doors.

- Start the System: Turn the system back on and ensure it’s running correctly.

Choosing the Right Filters

As you might assume, it’s important to select the right filters for your dust collection system. Using the wrong filter for your system will make it run less efficiently. Filters are designed for specific tasks, so you will want to match them to the type of dust and particles your shop generates.

For instance, if you work with wood, you’ll need filters designed to capture fine wood dust. If your operations involve metal or chemicals, the filters should be tailored to those materials.

Additionally, consider the Minimum Efficiency Reporting Value (MERV) rating of the filters. A higher MERV rating indicates better filtration efficiency, trapping even the tiniest particles. If you choose the right filters, your system operates at peak performance. If you don’t choose the right filter, your system fails to deliver on its promise of cleaner air.

Routine maintenance habits are the backbone of an efficiently operating dust collection system. Such practices are the building blocks of a healthier, safer, and more productive woodshop. Next, we will explore the finer points of system inspections and troubleshooting common issues. By the end, you should know everything you need to keep your dust collection system in top shape.

System Inspections

For routine maintenance to work well, you’ll want to learn how to do systematic inspections of your system. These thorough check-ups ensure that every component of your system is functioning as it should. System inspections are like the detailed medical check-ups for your dust collection system. They allow you to catch issues before they become major concerns.

The Importance of Thorough System Inspections

I cannot overstate the significance of thorough system inspections. They are your proactive approach to identifying problems, even those not immediately visible. A well-functioning dust collection system relies on every component working in harmony. If one part falters, it can affect the entire system’s efficiency and safety.

By conducting regular inspections, you ensure the longevity of your equipment. As a result, you continue having a clean and safe workspace and prevent small issues from escalating into expensive and time-consuming repairs.

Key Components to Check During an Inspection

An effective system inspection involves a detailed examination of all the essential components that make up your dust collection system. These include, but are not limited to:

- Ductwork: Check for any leaks, blockages, or damage in the ducts that transport dust from the source to the collector.

- Hoods: Examine the hoods that capture dust at their source, ensuring they are properly aligned and not damaged.

- Fans: Inspect the fans to ensure they are in good working condition and there are no signs of wear or imbalance.

- Filters: Check the filters for signs of clogging, damage, or wear, and replace them if necessary.

- Electrical Components: Ensure all electrical connections are secure and free of corrosion or damage.

- Access Panels and Doors: Make sure that all access panels and doors are secure and functioning correctly.

- Airflow: Verify that the system is maintaining the recommended airflow to capture and contain dust effectively.

Conducting a System Inspection: A Step-by-Step Guide

Here’s a step-by-step guide to conducting a systematic inspection of your dust collection system:

- Put Safety First: Always ensure that the system is turned off and unplugged before you begin. Safety should be the top priority.

- Start with Access Points: Open access panels and doors to gain access to the system’s components.

- Do a Visual Inspection: Start with a visual examination of the ductwork, hoods, and filters. Look for any signs of damage, blockages, or wear.

- Check Electrical Components: Inspect all electrical connections and components to ensure they are secure and free from damage.

- Test the Fan: Turn on the system briefly to check the fan. Listen for any unusual noises and ensure it’s running smoothly.

- Examine the Filter: Examine the filters for signs of clogging or damage. If your system has a differential pressure gauge, check its reading. A significant increase in pressure may indicate the need for filter replacement.

- Measure the Airflow: Use an anemometer or airflow measuring device to ensure that the system is maintaining the recommended airflow.

- Document Findings: Keep a record of your inspection findings, noting any issues that require attention.

- Close and Secure: After completing the inspection, close and secure all access panels and doors.

Safety Measures During Inspections

Don’t take shortcuts. It’s not worth compromising your safety during system inspections. Here are some key safety measures to keep in mind:

- Always turn off and unplug the system before inspecting it.

- Ensure that your work area is well-lit to spot any potential issues.

- Use appropriate safety gear, such as gloves and safety glasses, to protect yourself during inspections.

- Be cautious when working around electrical components. If you’re not experienced in electrical matters, consult a professional.

System inspections are the proactive measures that keep your dust collection system running smoothly. Doing them regularly not only safeguards your equipment but also ensures a clean, safe, and efficient shop. We’re going to shift now to the art of troubleshooting common issues. Our goal is to equip you with the knowledge to address problems swiftly and effectively.

Troubleshooting Common Issues

Now that you know how to do system inspections, it’s time to equip yourself with the skills to troubleshoot common issues that can arise in dust collection systems. Every shop owner encounters these challenges at some point. By learning how to diagnose and fix them, you can prevent minor problems from evolving into major headaches.

Common Problems and Challenges

Let’s start by identifying some of the common issues that can affect your dust collection system:

- Reduced Airflow: A decrease in the system’s airflow can be caused by clogged filters, damaged ductwork, or a malfunctioning fan.

- Filter Clogging: Filters can become clogged over time, reducing their efficiency in capturing dust.

- Leaks in Ductwork: Holes or leaks in the ductwork can lead to the loss of airflow and reduced system efficiency.

- Excessive Noise: Unusual noises from the fan or other components may indicate imbalances, wear, or damage.

- System Overheating: Overheating can result from various issues, including fan motor problems or electrical issues.

- Inefficient Hood Placement: If the hoods are not correctly positioned to capture dust at the source, the system’s efficiency is compromised.

Solutions and Tips for Diagnosing and Fixing Issues

- Reduced Airflow: If you notice reduced airflow, start by checking the filters. Clogged filters are a common cause. Replace them if needed. If the problem persists, inspect the ductwork for leaks or blockages and ensure the fan is functioning correctly.

- Filter Clogging: Regularly inspect and clean or replace filters according to your system’s guidelines. This prevents filters from becoming clogged and affecting the system’s efficiency.

- Leaks in Ductwork: Conduct a thorough inspection of the ductwork to identify any holes or leaks. Seal these leaks with appropriate materials to restore optimal airflow.

- Excessive Noise: Unusual noises may indicate imbalances in the fan, worn bearings, or damaged fan blades. Inspect and address these issues promptly to prevent further damage.

- System Overheating: Overheating can result from a malfunctioning fan motor or electrical problems. Check for loose or damaged electrical connections, and ensure the fan motor is operating smoothly. If necessary, consult an electrician or technician for repairs.

- Inefficient Hood Placement: Ensure that hoods are correctly positioned to capture dust at the source. Adjust the hoods’ placement if necessary to improve efficiency.

Early Detection and Prevention

One of the most significant benefits of troubleshooting common issues is that you prevent more severe problems.

When you detect and resolve problems early, you can save time, money, and the hassle of major system breakdowns.

Your first line of defense in early issue detection is regular system inspections. During these inspections, keep an eye out for any signs of common problems. Addressing them promptly not only maintains your system’s efficiency but also prevents minor issues from escalating.

In addition to regular inspections, listen to your system. Unusual noises, changes in airflow, or temperature irregularities are often early indicators of potential problems. By being attentive and proactive, you can keep your dust collection system in prime condition.

By identifying problems early and taking the right steps to address them, you can ensure the ongoing efficiency and longevity of your dust collection system. As we close out this article, let’s see how proper maintenance and issue resolution can translate into substantial cost savings for your shop.

Regular Maintenance as a Cost-Saving Strategy

In our journey through maintaining a dust collection system, we’ve explored the intricacies of keeping your system in optimal condition. However, I want to highlight again that regular maintenance is more than just a necessary chore – it’s a cost-saving strategy that can make a substantial difference for your shop in the long run. Let’s delve into the specifics of how proper maintenance is a wise investment.

How Proper Maintenance Reduces Long-Term Costs

When you invest time and effort in the regular maintenance of your dust collection system, you’re making a strategic move to reduce long-term costs. Here’s how it works:

- Extended Equipment Lifespan: Well-maintained systems experience less wear and tear. Filters last longer, fans operate efficiently, and components stay in top shape. This translates to fewer breakdowns and replacements, saving you substantial expenses.

- Preventing Major Repairs: Timely maintenance detects and addresses minor issues before they escalate into significant problems. Minor repairs are more cost-effective and less disruptive than major overhauls.

- Optimal Operational Efficiency: A clean and well-maintained system operates at peak efficiency. It captures and contains dust effectively, reducing energy consumption and operating costs.

- Reduced Energy Consumption: Dust collection systems consume less energy when they are well-maintained. Efficient fans and clean filters require less power to maintain proper airflow, resulting in lower electricity bills.

- Improved Safety and Compliance: Avoiding issues that lead to dust explosions or fires prevents potential damage and regulatory fines. Maintaining a safe workplace is a crucial aspect of cost-saving through proper maintenance.

Impact on Equipment Longevity and Operational Efficiency

The heart of the matter is that proper maintenance is directly linked to equipment longevity and operational efficiency.

Here’s how it makes a difference:

- Equipment Longevity: Consider your dust collection system as an investment. The longer it operates efficiently, the more value it provides. Routine maintenance ensures that your system’s components, from filters to fans, last longer, delaying the need for costly replacements.

- Operational Efficiency: An efficient operating system saves you money in multiple ways. It captures more dust, ensuring a cleaner and safer environment. This reduces the need for extensive cleaning or dust removal, saving you both time and money.

- Worker Productivity: A clean and safe woodshop is more conducive to work. When your employees work in a healthier environment, they are more productive, leading to better output and higher profits.

Proper maintenance isn’t just about preserving the health of your dust collection system; it’s a strategic investment that translates into substantial cost savings over time. By prioritizing maintenance, you’re not only safeguarding your system but also making sure your woodshop succeeds for many years to come.

Conclusion

Do you feel comfortable navigating the art of dust collection system maintenance now? Remember that it’s not just a chore – it’s a strategic investment in your woodshop’s success and sustainability.

At Lapp Millwright, we understand the importance of proper maintenance and the critical role it plays in the longevity of your dust collection system. Our commitment is to assist you every step of the way. Whether you need personalized advice, system maintenance, or services, we’re here to help. Reach out to us to explore how we can enhance the efficiency of your woodshop.

We offer,

- INDUSTRIAL DUST COLLECTION SYSTEMS

- ECONOMY DUST COLLECTION SYSTEMS

- SMOKE & FUME COLLECTION

- BUCKET ELEVATORS

- INDUSTRIAL FILTERS

- VENTILATION DUCTWORK

- NFPA COMPLIANCE

- SERVICE & REPAIRS

- PREVENTATIVE MAINTENANCE PROGRAMS

Your journey toward a cleaner, safer, and more cost-effective work environment begins with maintenance. We appreciate your time and interest in this blog post and invite you to explore the other resources and services Lapp Millwright has to offer. Together, we can ensure your woodshop thrives.